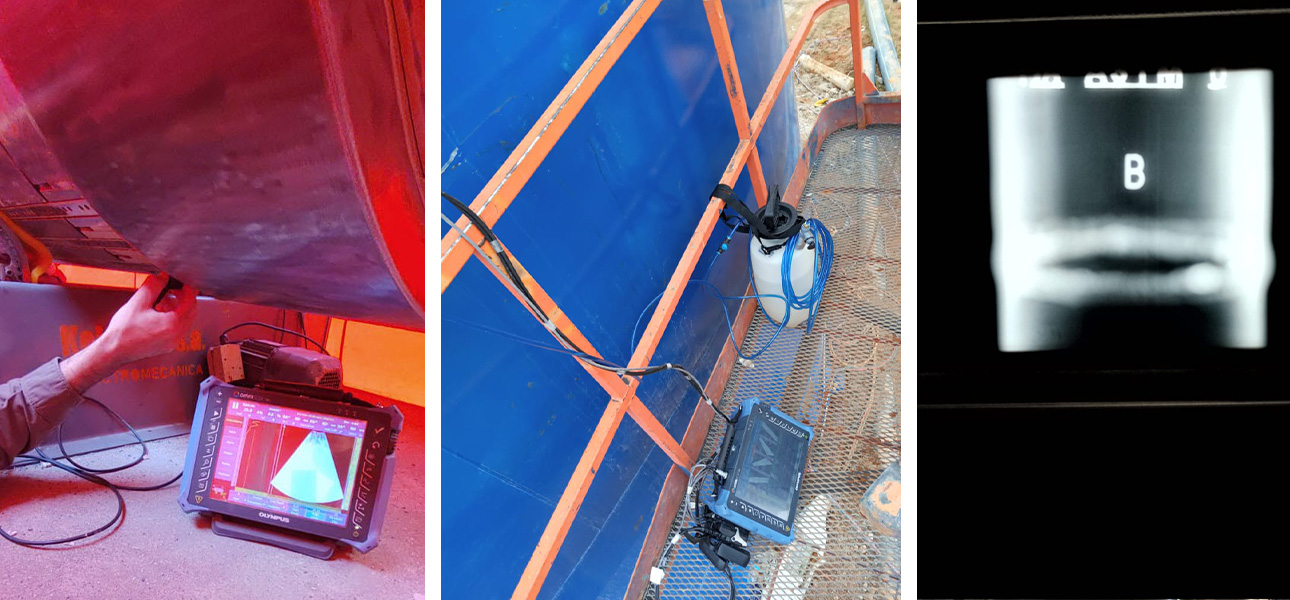

Quality Control Area – Non Destructive Testing Services

Our QA team has specialized personnel, state-of-the-art equipment and infrastructure that allows us to guarantee the quality of our Clients' projects. When performing each test and inspection, we apply standards, codes, specifications in accordance with the design and construction of the equipment or elements that we inspect. We are qualified to develop the following testing techniques:

- Industrial gamma radiography

- Industrial Radiography

- Penetrating liquids

- Magnetic Particle Inspection

- Thickness Measurement

- Volumetric Ultrasound

- Paint and Coating Tests: Verification of thicknesses, adhesion tests, Holiday tests.

- Hydraulic and pneumatic tests

- Vacuum Box

- Internal & External Visual Inspection

- Level Welding Inspectors - IRAM-IAS U500-169 Standard

- Inspectors of E.N.D. Leveled by IRAM-CNEA 9712 (ISO 9712)

- Inspectors of E.N.D. Leveled by SNT-TC-1A

- Level 3 in UT/RT/PT/MT validated by ASME

- Inspectors for mechanical works, pipes, electricity, instrumentation, civil, insulation and coatings.

- Inspectors with NACE certifications

- Personnel authorized by the Nuclear Regulatory Authority and Undersecretary of Health